Edge Computing Powering the Next-Gen Factory

The Rise of the Smart Factory

The modern factory is undergoing a dramatic transformation, driven by the need for increased efficiency, reduced downtime, and improved product quality. This evolution is fueled by the convergence of several technologies, most notably the Internet of Things (IoT), artificial intelligence (AI), and, increasingly, edge computing. No longer are factories simply places where raw materials are transformed into finished goods; they’re becoming complex, interconnected ecosystems of data-generating machines and processes.

Edge Computing: Bridging the Gap Between Data and Action

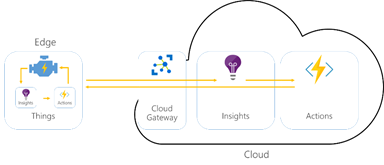

Traditional cloud computing, while powerful, often suffers from latency issues when dealing with the massive amounts of real-time data generated by industrial equipment. This delay can be problematic in a factory setting, where quick responses to anomalies are crucial for maintaining productivity and preventing costly downtime. Edge computing addresses this challenge by processing data closer to its source – the factory floor itself. This significantly reduces latency, enabling faster decision-making and immediate action based on real-time insights.

Real-Time Analytics and Predictive Maintenance

One of the most impactful applications of edge computing in factories is predictive maintenance. By analyzing sensor data from machines in real-time, edge devices can identify potential equipment failures before they occur. This allows for proactive maintenance scheduling, minimizing downtime and preventing costly repairs. This predictive capability not only saves time and money but also enhances overall operational efficiency.

Enhanced Quality Control and Improved Product Traceability

Edge computing empowers factories to implement sophisticated quality control systems. Real-time data analysis from various stages of the production process allows for immediate identification of defects or inconsistencies. This allows for quicker intervention, reducing waste and improving the overall quality of finished goods. Furthermore, edge computing facilitates improved product traceability, allowing for easy tracking of products throughout their lifecycle, from raw material sourcing to final delivery.

Optimizing Production Processes through Data-Driven Insights

The wealth of data generated by a smart factory can be overwhelming without effective analysis. Edge computing provides the computational power to process this data locally, providing real-time insights into production processes. This allows for identification of bottlenecks, optimization of workflows, and adjustments to improve efficiency and throughput. This data-driven approach leads to continuous improvement and helps factories stay ahead of the competition.

Enhancing Workforce Safety and Collaboration

Beyond optimizing production, edge computing enhances workforce safety and collaboration. Real-time monitoring of equipment and worker activity allows for immediate identification of potential hazards. This proactive approach minimizes workplace accidents and ensures a safer working environment. Furthermore, edge computing facilitates seamless communication and collaboration between workers, engineers, and management, enhancing overall operational efficiency.

Security Considerations in the Edge Environment

With the increased reliance on interconnected devices and data processing at the edge, security becomes paramount. Robust security measures are essential to protect against cyber threats and data breaches. This includes implementing strong access controls, encryption protocols, and regular security audits. A well-defined security strategy is vital for the successful deployment of edge computing in a factory setting.

The Future of Edge Computing in Manufacturing

The integration of edge computing in manufacturing is still in its early stages, yet its potential is vast. As technology continues to evolve, we can expect to see even more sophisticated applications of edge computing in factories. This will lead to even greater efficiency, improved product quality, enhanced safety, and a more sustainable and resilient manufacturing industry. The smart factory powered by edge computing is not just the future; it’s the present, and it’s rapidly transforming the way goods are produced globally. Click here to learn about edge software for smart factories.

Edge Computing Smart Factories’ New Powerhouse

The Rise of Edge Computing in Smart Factories

Smart factories are rapidly evolving, driven by the need for increased efficiency, flexibility, and responsiveness. Centralized cloud computing, while powerful, often struggles to keep up with the real-time demands of a modern manufacturing environment. This is where edge computing steps in, offering a powerful solution by processing data closer to the source – the factory floor itself. This shift is transforming how manufacturers collect, analyze, and act upon data, leading to significant improvements across the board.

Real-Time Data Processing: The Key Advantage

One of the biggest benefits of edge computing in smart factories is the ability to process data in real-time. Traditional cloud-based systems often experience latency, meaning there’s a delay between data generation and analysis. In a manufacturing setting, this delay can be costly, leading to production bottlenecks, quality issues, and missed opportunities for optimization. Edge computing eliminates this latency, allowing for immediate responses to changing conditions. This allows for quicker adjustments to machinery, preventing downtime and maximizing output.

Enhanced Machine-to-Machine Communication (M2M)

Smart factories rely heavily on seamless communication between machines. Edge computing facilitates this by providing a localized network for data exchange. This improved M2M communication allows for better coordination between different parts of the production process, leading to smoother workflows and reduced errors. The localized nature of the data processing also improves security, as sensitive data doesn’t need to travel across a wider network, reducing the risk of breaches.

Improved Predictive Maintenance and Reduced Downtime

Predictive maintenance is crucial for maximizing uptime in a manufacturing setting. By analyzing sensor data from machines in real-time, edge computing allows for early detection of potential problems. This allows maintenance teams to address issues before they escalate into major breakdowns, minimizing downtime and reducing repair costs. The ability to predict and prevent equipment failures is a significant advantage, leading to substantial cost savings and increased productivity.

Boosting Operational Efficiency and Flexibility

Edge computing contributes to a more efficient and flexible factory environment. By automating tasks and processes, factories can operate more smoothly. Real-time data analysis allows for dynamic adjustments to production schedules based on current demand and resource availability. This flexibility is essential in today’s dynamic market, allowing manufacturers to respond quickly to changes in customer orders and market conditions. This agility is a major competitive advantage in a fast-paced global market.

Strengthened Cybersecurity Measures

While connected systems offer significant benefits, they also introduce cybersecurity risks. Edge computing mitigates these risks by keeping sensitive data localized. By processing and analyzing data at the edge, the amount of data needing to travel across a potentially vulnerable network is reduced, thus minimizing the exposure to cyber threats. This layered security approach provides a more robust defense against potential attacks.

Enabling Advanced Analytics and AI at the Edge

Edge computing enables the deployment of sophisticated analytics and artificial intelligence algorithms directly within the factory. This allows for faster insights and more immediate actions based on the analyzed data. AI-powered systems can be used for anomaly detection, quality control, and process optimization, leading to significant improvements in efficiency and product quality. The on-site processing also reduces the reliance on cloud resources for complex computations, further accelerating the decision-making process.

Scalability and Future-Proofing Smart Factories

The modular nature of edge computing allows for easy scalability as factory needs evolve. As production expands or new technologies are integrated, the edge computing infrastructure can be easily adapted to meet the growing demands. This adaptability is crucial for future-proofing smart factories and ensuring their continued competitiveness in a rapidly changing technological landscape. It allows for a smooth and efficient transition to even more advanced technologies in the future.

Challenges and Considerations

While edge computing presents numerous advantages, some challenges need to be considered. Managing and maintaining a distributed edge computing infrastructure can be complex, requiring specialized skills and expertise. Ensuring data consistency and security across multiple edge nodes also demands careful planning and implementation. Addressing these challenges requires a strategic approach and investment in the right technologies and personnel. Please click here to learn about edge computing for smart factories.