Extended Producer Responsibility EPR Market Growth Rise

Is the Extended Producer Responsibility (EPR) market poised for explosive growth? Absolutely. As awareness of environmental issues intensifies and the pressure mounts on businesses to adopt sustainable practices, Extended Producer Responsibility (EPR) is rapidly becoming a cornerstone of waste management strategies worldwide. This article delves into the factors driving this market growth, exploring the mechanics of EPR schemes and their profound impact on producers, consumers, and the planet. We’ll address common questions and concerns surrounding EPR, offering a clear understanding of its current state and future trajectory.

Key Takeaways:

- The Extended Producer Responsibility (EPR) market is experiencing significant growth due to increased environmental awareness and stricter regulations.

- EPR schemes hold producers accountable for the end-of-life management of their products, incentivizing eco-design and efficient recycling.

- This growth presents opportunities for businesses to innovate in sustainable packaging and waste management solutions.

- Understanding EPR is vital for any company involved in the production, distribution, or sale of goods.

Understanding the Rise of the Extended Producer Responsibility (EPR) Market

The Extended Producer Responsibility (EPR) market is not just growing; it’s evolving. Traditionally, waste management has been the sole responsibility of municipalities and taxpayers. EPR shifts this burden to producers, making them financially and/or physically responsible for the collection, sorting, recycling, and proper disposal of their products and packaging. This simple shift has a cascading effect. It incentivizes producers to design products that are easier to recycle, use less material, and are more durable. It also fosters the development of robust recycling infrastructure and creates new markets for recycled materials.

Several factors are fueling the growth of the Extended Producer Responsibility (EPR) market. Firstly, consumer demand for sustainable products and practices is at an all-time high. People are increasingly aware of the environmental impact of their purchases and are actively seeking out brands that are committed to sustainability. Secondly, governments around the world are implementing stricter environmental regulations, including EPR schemes, to reduce waste and promote a circular economy. This regulatory pressure forces producers to comply with EPR requirements or face penalties. Thirdly, advancements in recycling technologies are making it more feasible and cost-effective to recycle a wider range of materials, further driving the growth of the EPR market. Finally, businesses are beginning to recognize the economic benefits of EPR, such as reduced material costs, improved brand reputation, and access to new markets.

The Mechanics of Extended Producer Responsibility (EPR) Schemes

Extended Producer Responsibility (EPR) schemes vary depending on the product type and the specific regulations in place. However, most schemes share some common elements. Producers are typically required to register with a regulatory body and report on the amount of products and packaging they place on the market. They then pay a fee, which is used to finance the collection, sorting, recycling, and disposal of these materials. The fee may be based on the weight of the material, its recyclability, or other factors.

In some cases, producers are responsible for physically managing the end-of-life of their products. This may involve setting up their own collection and recycling programs or working with third-party organizations to do so. In other cases, producers simply pay a fee and the responsibility for managing the waste is handled by a government agency or a producer responsibility organization (PRO). The specific structure of the EPR scheme depends on the local context and the policy objectives of the government. For example, some schemes focus on specific materials, such as packaging or electronics, while others cover a wider range of products.

The effectiveness of an EPR scheme depends on several factors, including the level of enforcement, the transparency of the system, and the engagement of stakeholders. It is important for us to have clear and consistent regulations, effective monitoring and enforcement mechanisms, and strong partnerships between producers, recyclers, and government agencies.

The Impact of Extended Producer Responsibility (EPR) on Businesses

Extended Producer Responsibility (EPR) has a significant impact on businesses, both positive and negative. On the one hand, it can increase costs for producers, particularly those who are not already focused on sustainability. The fees associated with EPR can be substantial, and the costs of redesigning products and packaging can also be significant. On the other hand, EPR can also create opportunities for businesses. It incentivizes them to innovate in sustainable packaging and waste management solutions, which can lead to cost savings and improved brand reputation.

For example, a company that designs its products to be easily recyclable can reduce its EPR fees and attract environmentally conscious consumers. A company that uses recycled materials in its products can reduce its reliance on virgin materials and lower its production costs. A company that partners with recycling organizations can gain access to new markets for its recycled materials. EPR can also help companies to reduce their environmental footprint and improve their overall

Product Lifecycle Management PLM for Sustainability Growth

Is your business ready to embrace sustainability and drive significant growth? Modern consumers demand eco-conscious products, and companies are increasingly aware of their environmental responsibilities. Integrating sustainability into your core operations is no longer optional; it’s essential for long-term success. One of the most powerful tools for achieving this is Product Lifecycle Management (PLM) for Sustainability.

Key Takeaways:

- Product Lifecycle Management (PLM) for Sustainability integrates eco-friendly practices into every stage of a product’s journey, from design to disposal.

- It helps reduce environmental impact by optimizing resource usage, minimizing waste, and promoting circular economy principles.

- Implementing PLM for sustainability can lead to increased brand reputation, customer loyalty, and long-term profitability.

- Successfully integrating PLM with sustainability requires a strategic approach, the right technology, and a commitment to continuous improvement across the entire organization.

Understanding the Importance of Product Lifecycle Management (PLM) for Sustainability

In today’s world, sustainability is more than just a buzzword; it’s a fundamental business imperative. Consumers are actively seeking products that are not only high-quality and affordable but also environmentally responsible. Regulatory pressures are mounting, and companies are being held accountable for their environmental footprint. Therefore, businesses must proactively incorporate sustainability into their core strategies to thrive in the long run.

Product Lifecycle Management (PLM) for Sustainability provides a framework for integrating sustainability considerations into every stage of a product’s lifecycle. This includes design, sourcing, manufacturing, distribution, use, and end-of-life management. By using PLM principles, companies can gain a holistic view of their environmental impact and identify opportunities for improvement.

This approach helps minimize waste, reduce energy consumption, optimize material usage, and promote circular economy principles. It also allows companies to track and report on their sustainability performance, which is increasingly important for attracting investors and building trust with customers. We firmly believe that businesses that prioritize sustainability through PLM will be better positioned to succeed in the future.

Benefits of Using Product Lifecycle Management (PLM) for Sustainability

Implementing Product Lifecycle Management (PLM) for Sustainability offers a multitude of benefits that extend beyond environmental responsibility. These advantages can significantly impact a company’s bottom line and long-term competitiveness.

- Reduced Costs: By optimizing resource usage and minimizing waste, companies can significantly reduce their operating costs. PLM helps identify inefficiencies in the supply chain, streamline manufacturing processes, and design products that are more durable and require less maintenance.

- Improved Brand Reputation: Consumers are increasingly loyal to brands that demonstrate a commitment to sustainability. Implementing PLM for sustainability can enhance a company’s image and attract environmentally conscious customers. This can lead to increased sales and market share.

- Enhanced Innovation: Integrating sustainability into the product development process can spark creativity and innovation. It can lead to the development of new products and services that are both environmentally friendly and meet the evolving needs of customers.

- Compliance with Regulations: Regulatory requirements related to environmental protection are becoming more stringent. PLM for sustainability helps companies stay ahead of the curve and ensure compliance with these regulations, avoiding costly penalties and reputational damage.

- Supply Chain Transparency: PLM systems can provide greater visibility into the environmental performance of suppliers, allowing companies to make informed decisions and choose partners who share their commitment to sustainability.

Implementing Product Lifecycle Management (PLM) for Sustainability Effectively

Successfully integrating Product Lifecycle Management (PLM) for Sustainability requires a strategic approach and a commitment to continuous improvement. Here are some key steps to consider:

- Assess your current state: Begin by evaluating your current product development processes and identifying areas where sustainability can be improved. This includes assessing your environmental footprint, resource consumption, and waste generation.

- Set clear goals and objectives: Define specific, measurable, achievable, relevant, and time-bound (SMART) goals for your sustainability initiatives. These goals should align with your overall business strategy and be communicated clearly to all stakeholders.

- Select the right PLM software: Choose a PLM system that can support your sustainability goals. Look for features such as environmental impact assessment, material compliance tracking, and circular economy modeling.

- Train your team: Provide your team with the training and resources they need to effectively use the PLM system and integrate sustainability into their daily work.

- Collaborate with suppliers: Work closely with your suppliers to ensure that they are also committed to sustainability. Share your goals and expectations, and provide them with the support they need to improve their environmental performance.

- Monitor and measure progress: Regularly monitor and measure your progress towards your sustainability goals. Use data to identify areas where you are succeeding and areas where you need to improve.

- Continuously improve: Sustainability is an ongoing journey. Continuously seek out new ways to improve your environmental performance and reduce your impact on the planet.

Overcoming Challenges in Product Lifecycle Management (PLM) for Sustainability

While the benefits of Product Lifecycle Management (PLM) for Sustainability are clear, implementing it effectively can present some challenges. Addressing these

Remanufacturing Processes Global Market Growth Rise

The remanufacturing sector is experiencing a significant surge in global demand. This growth is fueled by a confluence of factors, including increased environmental awareness, stricter regulations, and the compelling economic advantages remanufacturing processes offer. Businesses and consumers alike are increasingly recognizing the value in extending the lifespan of products, reducing waste, and conserving resources. The shift towards a more circular economy model is propelling remanufacturing into the mainstream.

Key Takeaways:

- The global remanufacturing market is experiencing rapid growth due to environmental and economic pressures.

- Remanufacturing processes offer a sustainable alternative to traditional manufacturing, reducing waste and conserving resources.

- The automotive and industrial sectors are leading the way in adopting remanufacturing practices.

- Government incentives and consumer awareness are further driving the adoption of remanufacturing worldwide.

Understanding the Growth of Remanufacturing Processes

The growth of remanufacturing processes is not just a trend; it’s a fundamental shift in how we approach production and consumption. Traditional “take-make-dispose” models are increasingly unsustainable in a world facing resource scarcity and environmental challenges. Remanufacturing provides a viable and profitable alternative. It involves restoring used products to like-new condition through a rigorous process of disassembly, cleaning, inspection, repair, and replacement of worn or obsolete parts. This process allows us to reuse existing materials, significantly reducing the demand for new raw materials and the energy required to extract and process them.

Furthermore, technological advancements are making remanufacturing processes more efficient and cost-effective. Automated systems, advanced diagnostic tools, and improved materials are contributing to higher quality remanufactured products that can compete with new products in terms of performance and reliability. This technological progress is empowering businesses to scale up their remanufacturing operations and reach a wider customer base.

Economic Advantages of Remanufacturing Processes

Beyond its environmental benefits, remanufacturing processes offer significant economic advantages for both businesses and consumers. For manufacturers, remanufacturing can create new revenue streams by extending the life cycle of their products and capturing value from returned or used items. It also allows them to reduce their dependence on volatile raw material prices and mitigate supply chain disruptions. This can lead to greater profitability and resilience in the face of economic uncertainty.

For consumers, remanufactured products often come with a lower price tag than new products, making them an attractive option for those seeking value for money. This affordability, combined with the assurance of quality and performance, is driving increased consumer demand for remanufactured goods. Additionally, the growth of the remanufacturing sector is creating new jobs and opportunities in local economies, further contributing to its economic appeal. The rise of online marketplaces and e-commerce platforms has also made it easier for consumers to access and purchase remanufactured products. This increased accessibility is playing a crucial role in driving market growth and expanding the reach of the remanufacturing industry.

The Role of Automotive and Industrial Remanufacturing Processes

The automotive and industrial sectors are at the forefront of the remanufacturing movement. In the automotive industry, remanufactured parts such as engines, transmissions, and alternators are widely used in vehicle repairs and maintenance. These parts offer a cost-effective and environmentally friendly alternative to new parts, helping to reduce waste and conserve resources. The automotive industry’s established infrastructure for core collection and distribution has played a significant role in the success of automotive remanufacturing.

Similarly, in the industrial sector, remanufacturing processes are used to restore and upgrade heavy machinery, equipment, and components. This is particularly important in industries such as manufacturing, mining, and construction, where equipment is often subject to harsh operating conditions and high levels of wear and tear. Remanufacturing allows companies to extend the lifespan of their assets, reduce downtime, and lower maintenance costs. As industries face increasing pressure to reduce their environmental footprint and improve resource efficiency, remanufacturing is becoming an increasingly attractive and necessary solution. The focus on predictive maintenance and data analytics is further optimizing remanufacturing processes in these sectors. These technologies allow us to better anticipate component failures and schedule remanufacturing activities proactively, minimizing disruptions and maximizing efficiency.

Government Support and Consumer Awareness for Remanufacturing Processes

Government policies and consumer awareness are playing a crucial role in accelerating the adoption of remanufacturing processes worldwide. Governments are increasingly recognizing the environmental and economic benefits of remanufacturing and are implementing policies to support its growth. These policies may include tax incentives, subsidies, and regulations that promote the use of remanufactured products and encourage businesses to adopt remanufacturing practices. By creating a favorable regulatory environment, governments can help to level the playing field and encourage greater investment in the remanufacturing sector.

Consumer awareness is also a key driver of market growth. As more consumers become aware of the environmental and economic benefits of remanufactured products, they are increasingly choosing these products over new alternatives. This increased demand is creating a virtuous cycle, encouraging more businesses to offer remanufactured products and

Smart Factory Software The Future of Manufacturing

The Rise of the Smart Factory

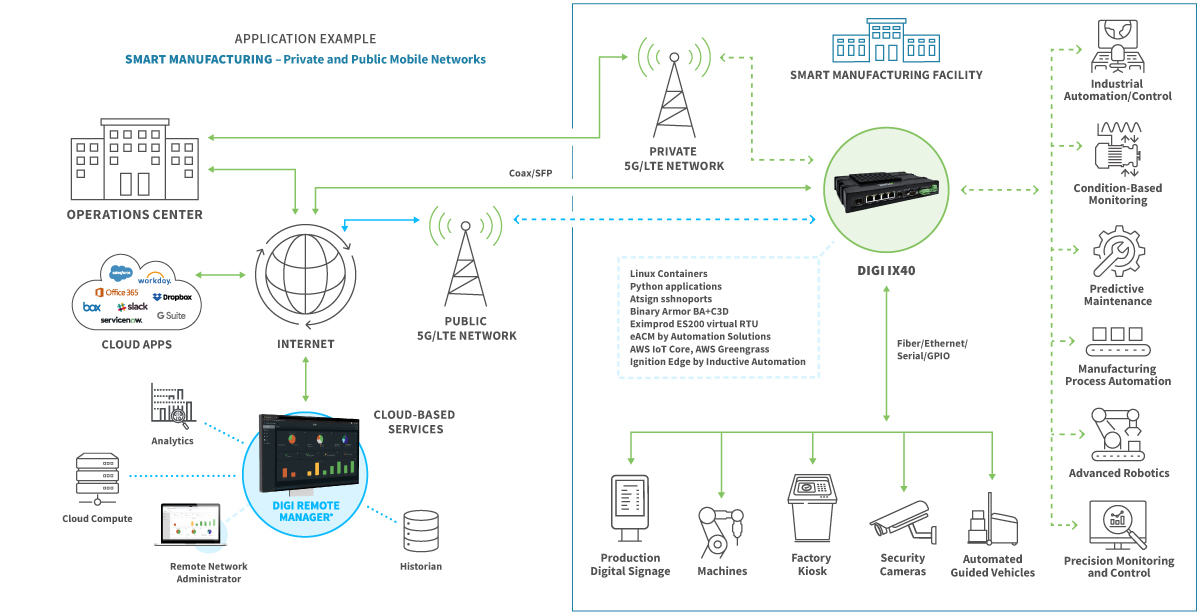

The manufacturing landscape is undergoing a dramatic transformation, driven by the convergence of advanced technologies like artificial intelligence (AI), the Internet of Things (IoT), big data analytics, and cloud computing. This convergence is fueling the rise of the smart factory, a highly automated and interconnected facility where data-driven insights optimize every aspect of production, from design and planning to manufacturing and delivery. No longer are factories simply places where goods are made; they’re becoming sophisticated, responsive ecosystems capable of adapting to changing market demands with unprecedented agility.

Smart Factory Software: The Brains of the Operation

At the heart of the smart factory lies sophisticated software. This isn’t just the traditional manufacturing execution system (MES) software; it’s a much more comprehensive and integrated platform that orchestrates the entire factory ecosystem. This software integrates data from various sources – machines, sensors, ERP systems, supply chain management systems – providing a single source of truth for all factory operations. This unified view enables real-time monitoring, predictive maintenance, and proactive adjustments to optimize efficiency and minimize downtime.

Predictive Maintenance: Preventing Problems Before They Happen

One of the most significant benefits of smart factory software is its ability to predict and prevent equipment failures. By analyzing data from sensors embedded in machinery, the software can identify patterns that indicate potential problems before they escalate into costly breakdowns. This predictive maintenance capability significantly reduces downtime, improves production efficiency, and extends the lifespan of equipment. Rather than relying on scheduled maintenance, factories can now perform maintenance only when and where it’s actually needed, maximizing uptime and minimizing waste.

Real-time Monitoring and Control: Staying Ahead of the Curve

Smart factory software provides real-time visibility into every aspect of the manufacturing process. Operators can monitor production in real time, identify bottlenecks, and make adjustments on the fly to keep production flowing smoothly. This real-time monitoring capability allows for immediate responses to unexpected events, minimizing disruptions and maximizing efficiency. The ability to react quickly to changing conditions is crucial in today’s dynamic market, where responsiveness is key to competitiveness.

Data Analytics: Unlocking Hidden Insights

The vast amounts of data generated by a smart factory can be overwhelming without the right tools to analyze it. Smart factory software incorporates advanced data analytics capabilities that can sift through this data, identify trends, and extract valuable insights. This data can be used to improve production processes, optimize resource allocation, reduce waste, and improve product quality. By uncovering hidden patterns and correlations within the data, manufacturers can make more informed decisions and continuously improve their operations.

Enhanced Collaboration and Communication: Breaking Down Silos

Traditional manufacturing often suffers from information silos, where different departments operate in isolation. Smart factory software breaks down these silos by providing a central platform for collaboration and communication. All stakeholders – from engineers and operators to managers and suppliers – can access the same information in real time, fostering better communication and collaboration. This enhanced communication streamlines processes, reduces errors, and improves overall efficiency.

Supply Chain Optimization: From Raw Materials to Finished Goods

Smart factory software extends beyond the factory floor, encompassing the entire supply chain. By integrating data from suppliers, distributors, and logistics providers, the software enables real-time visibility into the entire supply chain. This visibility enables better inventory management, optimized logistics, and improved supply chain responsiveness. Manufacturers can proactively address potential disruptions and ensure a steady flow of materials and components, minimizing delays and ensuring timely delivery of finished goods.

The Future of Manufacturing: A Seamless and Agile Ecosystem

Smart factory software is not just a collection of individual technologies; it’s a transformative force reshaping the future of manufacturing. It’s creating a more agile, efficient, and responsive industry capable of adapting to the ever-changing demands of the global market. The factories of tomorrow will be seamlessly interconnected ecosystems, leveraging data-driven insights to optimize every aspect of production, delivering higher quality products at lower costs, and responding to market fluctuations with unprecedented speed and agility. Read also about iot software for smart factories.

The Metaverse Revolutionizes Manufacturing

Enhanced Collaboration and Design

The metaverse offers a transformative shift in how manufacturing teams collaborate. Imagine engineers from different continents, wearing VR headsets, working together on a 3D model of a new engine. They can manipulate the design in real-time, discuss changes instantly, and visually inspect every detail, all without ever leaving their desks. This drastically reduces design cycles, improves communication, and fosters a more intuitive and collaborative design process. No more endless email chains or confusing 2D blueprints; the metaverse provides a shared, immersive workspace for seamless collaboration.

Digital Twins for Predictive Maintenance

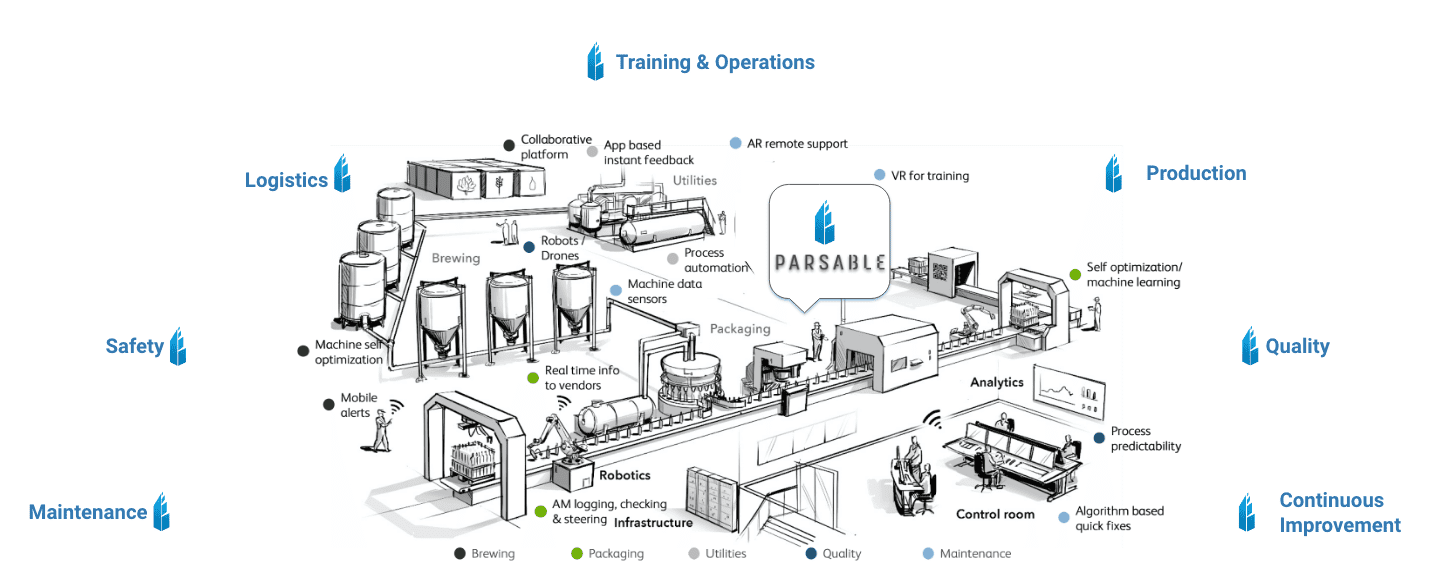

One of the most exciting applications of the metaverse in manufacturing is the creation and implementation of digital twins. A digital twin is a virtual replica of a physical asset, such as a machine or an entire factory floor. By using sensor data and AI, these digital twins can simulate real-world conditions and predict potential issues before they occur. This allows for proactive maintenance, reducing downtime, extending the lifespan of equipment, and significantly improving operational efficiency. Instead of reacting to failures, manufacturers can anticipate and prevent them, leading to significant cost savings and increased productivity.

Streamlined Training and Onboarding

Training new employees in a manufacturing environment can be complex, costly, and potentially dangerous. The metaverse provides a safe and effective alternative. New hires can undergo virtual training simulations, learning to operate machinery, understand safety protocols, and troubleshoot problems in a risk-free environment. This immersive learning experience is more engaging and effective than traditional methods, leading to faster onboarding and a more skilled workforce. Companies can even simulate complex scenarios, like equipment malfunctions or emergency situations, allowing trainees to develop crucial problem-solving skills in a controlled setting.

Improved Supply Chain Management

Supply chain disruptions have become a major challenge for manufacturers. The metaverse offers tools to improve visibility and efficiency throughout the supply chain. By creating a digital representation of the entire supply chain, manufacturers can track the movement of goods in real-time, anticipate potential delays, and optimize logistics. This improved transparency allows for quicker responses to disruptions, better inventory management, and reduced lead times, ultimately leading to more resilient and responsive supply chains. The virtual environment provides a platform for better communication and coordination among all stakeholders, from suppliers to distributors.

Remote Operations and Monitoring

In industries with remote or hazardous work environments, the metaverse offers a revolutionary approach to operations and monitoring. Workers can remotely control and monitor machinery and processes through VR interfaces, reducing the need for on-site personnel in dangerous situations. This not only improves safety but also allows for more efficient and precise control of operations. Imagine technicians remotely guiding complex repairs using augmented reality overlays, providing real-time instructions to on-site personnel, or monitoring the performance of equipment from a central control room, all through a metaverse platform.

Enhanced Customer Experience

The metaverse isn’t just limited to internal operations; it can also revolutionize the customer experience. Manufacturers can create virtual showrooms where customers can explore and interact with products in a realistic and immersive environment. This provides a more engaging and informative pre-purchase experience, allowing customers to better understand the product’s features and benefits before making a purchase. Companies can even offer virtual consultations and personalized product demonstrations, leading to increased customer satisfaction and brand loyalty. This immersive approach builds a stronger connection between the manufacturer and the customer.

Addressing the Challenges of Metaverse Adoption

While the potential benefits are significant, the adoption of metaverse technologies in manufacturing also faces challenges. The high initial investment in hardware and software, the need for skilled personnel to develop and implement metaverse applications, and the integration with existing systems are all considerable hurdles. Furthermore, ensuring data security and privacy in a shared virtual environment is crucial for successful implementation. Overcoming these challenges requires collaboration between manufacturers, technology providers, and regulatory bodies to establish standards and best practices for metaverse adoption in the manufacturing sector. This collaborative effort will drive the wider acceptance and integration of this revolutionary technology. Read also about the metaverse for smart factories.

Edge Computing Powering the Next-Gen Factory

The Rise of the Smart Factory

The modern factory is undergoing a dramatic transformation, driven by the need for increased efficiency, reduced downtime, and improved product quality. This evolution is fueled by the convergence of several technologies, most notably the Internet of Things (IoT), artificial intelligence (AI), and, increasingly, edge computing. No longer are factories simply places where raw materials are transformed into finished goods; they’re becoming complex, interconnected ecosystems of data-generating machines and processes.

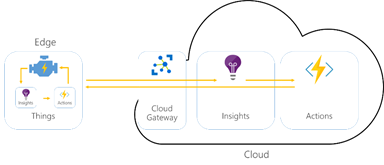

Edge Computing: Bridging the Gap Between Data and Action

Traditional cloud computing, while powerful, often suffers from latency issues when dealing with the massive amounts of real-time data generated by industrial equipment. This delay can be problematic in a factory setting, where quick responses to anomalies are crucial for maintaining productivity and preventing costly downtime. Edge computing addresses this challenge by processing data closer to its source – the factory floor itself. This significantly reduces latency, enabling faster decision-making and immediate action based on real-time insights.

Real-Time Analytics and Predictive Maintenance

One of the most impactful applications of edge computing in factories is predictive maintenance. By analyzing sensor data from machines in real-time, edge devices can identify potential equipment failures before they occur. This allows for proactive maintenance scheduling, minimizing downtime and preventing costly repairs. This predictive capability not only saves time and money but also enhances overall operational efficiency.

Enhanced Quality Control and Improved Product Traceability

Edge computing empowers factories to implement sophisticated quality control systems. Real-time data analysis from various stages of the production process allows for immediate identification of defects or inconsistencies. This allows for quicker intervention, reducing waste and improving the overall quality of finished goods. Furthermore, edge computing facilitates improved product traceability, allowing for easy tracking of products throughout their lifecycle, from raw material sourcing to final delivery.

Optimizing Production Processes through Data-Driven Insights

The wealth of data generated by a smart factory can be overwhelming without effective analysis. Edge computing provides the computational power to process this data locally, providing real-time insights into production processes. This allows for identification of bottlenecks, optimization of workflows, and adjustments to improve efficiency and throughput. This data-driven approach leads to continuous improvement and helps factories stay ahead of the competition.

Enhancing Workforce Safety and Collaboration

Beyond optimizing production, edge computing enhances workforce safety and collaboration. Real-time monitoring of equipment and worker activity allows for immediate identification of potential hazards. This proactive approach minimizes workplace accidents and ensures a safer working environment. Furthermore, edge computing facilitates seamless communication and collaboration between workers, engineers, and management, enhancing overall operational efficiency.

Security Considerations in the Edge Environment

With the increased reliance on interconnected devices and data processing at the edge, security becomes paramount. Robust security measures are essential to protect against cyber threats and data breaches. This includes implementing strong access controls, encryption protocols, and regular security audits. A well-defined security strategy is vital for the successful deployment of edge computing in a factory setting.

The Future of Edge Computing in Manufacturing

The integration of edge computing in manufacturing is still in its early stages, yet its potential is vast. As technology continues to evolve, we can expect to see even more sophisticated applications of edge computing in factories. This will lead to even greater efficiency, improved product quality, enhanced safety, and a more sustainable and resilient manufacturing industry. The smart factory powered by edge computing is not just the future; it’s the present, and it’s rapidly transforming the way goods are produced globally. Click here to learn about edge software for smart factories.

Smart Factories The Future of Manufacturing?

What is a Smart Factory?

A smart factory, also known as an intelligent factory, leverages technology to optimize every aspect of manufacturing. This isn’t just about automating individual processes; it’s about creating a connected ecosystem where machines, software, and people work together seamlessly. Think interconnected sensors, data analytics, AI-powered decision-making, and robotic automation all collaborating to create a highly efficient and responsive production environment. The ultimate goal is to improve productivity, reduce waste, and enhance product quality – all while adapting quickly to changing market demands.

Key Technologies Driving Smart Factories

Several key technologies underpin the smart factory revolution. The Internet of Things (IoT) plays a crucial role, connecting machines and devices to collect real-time data. This data is then analyzed using advanced analytics, including artificial intelligence and machine learning, to identify patterns, predict potential problems, and optimize processes. Robotics, particularly collaborative robots (cobots) are increasingly important for automating tasks, working alongside human employees. Cloud computing provides the necessary infrastructure for storing and processing vast amounts of data, while cybersecurity is crucial for protecting the sensitive information flowing through the network.

Benefits of Implementing Smart Factory Technologies

The advantages of transitioning to a smart factory are numerous. Perhaps the most significant is increased productivity. Automation and optimized processes lead to faster production cycles and higher output. Smart factories also excel at reducing waste, identifying inefficiencies, and minimizing downtime. Improved product quality is another key benefit, as data-driven insights enable manufacturers to fine-tune processes and eliminate defects. Furthermore, the enhanced flexibility and adaptability of smart factories allow manufacturers to respond quickly to changing customer demands and market trends. This agility can be a significant competitive advantage.

Challenges in Implementing Smart Factory Solutions

Despite the considerable benefits, implementing smart factory technologies presents significant challenges. The initial investment can be substantial, requiring substantial upfront capital expenditure on new equipment, software, and integration services. Furthermore, integrating disparate systems and legacy technologies can be complex and time-consuming, requiring specialized expertise. Data security is a paramount concern, as smart factories generate and process vast quantities of sensitive data. Ensuring robust cybersecurity measures is essential to prevent data breaches and disruptions. Finally, training employees to operate and maintain the new technologies is crucial to ensure a successful transition.

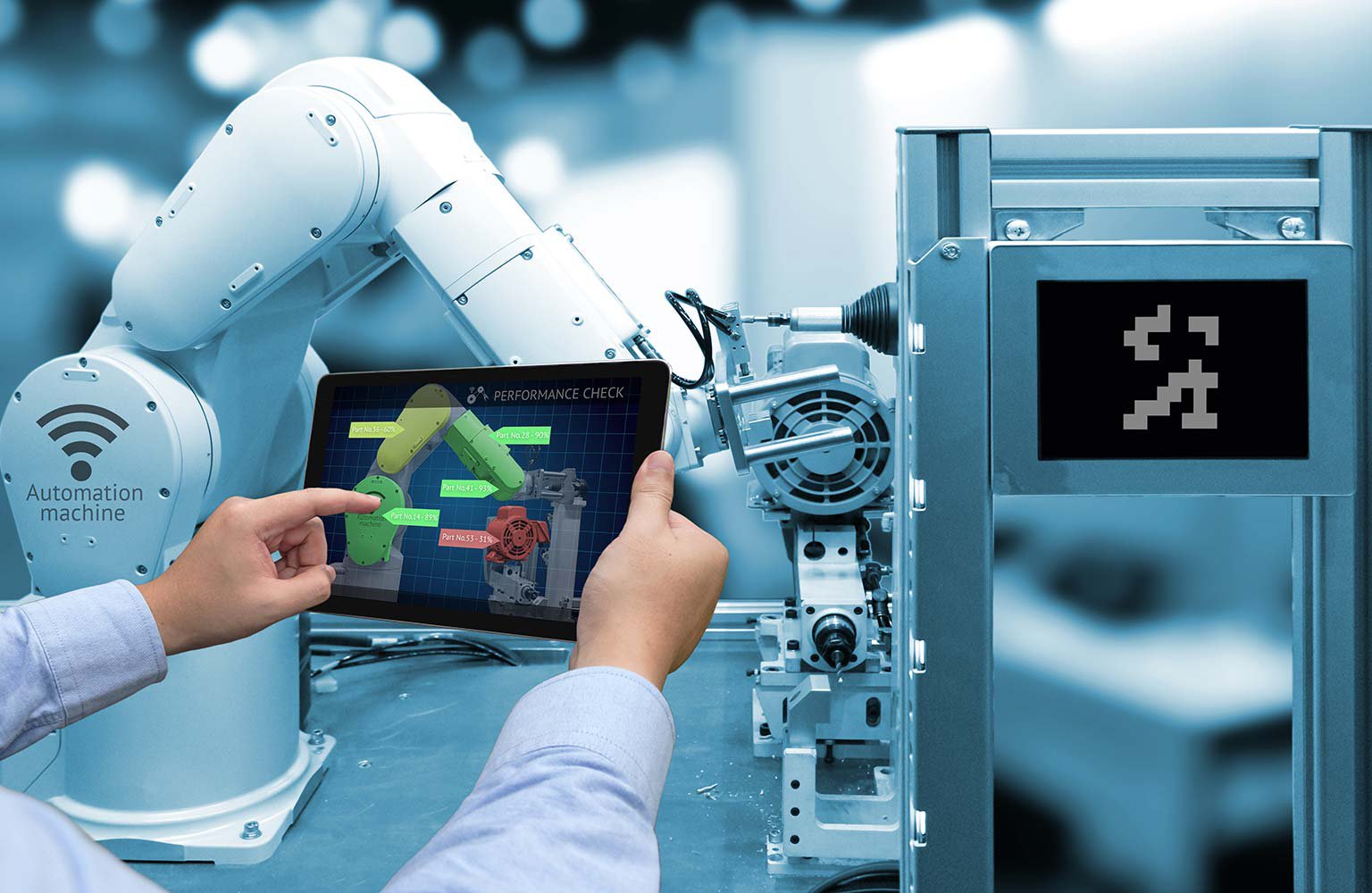

The Human Element in the Smart Factory

Contrary to popular misconceptions, smart factories don’t eliminate the need for human workers. Instead, they transform the nature of work. While automation handles repetitive and dangerous tasks, human employees are increasingly focused on higher-level activities such as problem-solving, innovation, and strategic decision-making. Reskilling and upskilling the workforce is essential to adapt to the changing demands of a smart factory environment. Focusing on collaborative robots allows humans and machines to work together, leveraging the strengths of each. This creates a more engaging and rewarding work environment.

The Future of Smart Factories and its Impact on Manufacturing

The future of smart factories is bright. Ongoing advancements in technology will continue to drive innovation and efficiency. We can expect to see greater integration of artificial intelligence, leading to even more autonomous and adaptable manufacturing processes. The rise of digital twins – virtual representations of physical factories – will further enhance simulation and optimization capabilities. As the technology becomes more accessible and affordable, more manufacturers will adopt smart factory solutions, leading to a more efficient, sustainable, and competitive global manufacturing landscape. This will not only impact manufacturing processes but also the wider economy, creating new job opportunities and driving economic growth.

Sustainability in Smart Factories

Smart factories are not only about efficiency but also sustainability. By optimizing processes and reducing waste, they contribute significantly to environmental responsibility. Data analytics can be used to monitor energy consumption and identify areas for improvement, leading to reduced carbon emissions. The ability to adapt to changing resource availability also contributes to a more sustainable manufacturing model. Integrating renewable energy sources further enhances the environmental credentials of smart factories. The focus on sustainability is increasingly crucial for businesses and consumers alike, making smart factory technology a cornerstone of environmentally conscious manufacturing. Please click here to learn about what smart factories are an example of.

Edge Computing Smart Factories’ New Powerhouse

The Rise of Edge Computing in Smart Factories

Smart factories are rapidly evolving, driven by the need for increased efficiency, flexibility, and responsiveness. Centralized cloud computing, while powerful, often struggles to keep up with the real-time demands of a modern manufacturing environment. This is where edge computing steps in, offering a powerful solution by processing data closer to the source – the factory floor itself. This shift is transforming how manufacturers collect, analyze, and act upon data, leading to significant improvements across the board.

Real-Time Data Processing: The Key Advantage

One of the biggest benefits of edge computing in smart factories is the ability to process data in real-time. Traditional cloud-based systems often experience latency, meaning there’s a delay between data generation and analysis. In a manufacturing setting, this delay can be costly, leading to production bottlenecks, quality issues, and missed opportunities for optimization. Edge computing eliminates this latency, allowing for immediate responses to changing conditions. This allows for quicker adjustments to machinery, preventing downtime and maximizing output.

Enhanced Machine-to-Machine Communication (M2M)

Smart factories rely heavily on seamless communication between machines. Edge computing facilitates this by providing a localized network for data exchange. This improved M2M communication allows for better coordination between different parts of the production process, leading to smoother workflows and reduced errors. The localized nature of the data processing also improves security, as sensitive data doesn’t need to travel across a wider network, reducing the risk of breaches.

Improved Predictive Maintenance and Reduced Downtime

Predictive maintenance is crucial for maximizing uptime in a manufacturing setting. By analyzing sensor data from machines in real-time, edge computing allows for early detection of potential problems. This allows maintenance teams to address issues before they escalate into major breakdowns, minimizing downtime and reducing repair costs. The ability to predict and prevent equipment failures is a significant advantage, leading to substantial cost savings and increased productivity.

Boosting Operational Efficiency and Flexibility

Edge computing contributes to a more efficient and flexible factory environment. By automating tasks and processes, factories can operate more smoothly. Real-time data analysis allows for dynamic adjustments to production schedules based on current demand and resource availability. This flexibility is essential in today’s dynamic market, allowing manufacturers to respond quickly to changes in customer orders and market conditions. This agility is a major competitive advantage in a fast-paced global market.

Strengthened Cybersecurity Measures

While connected systems offer significant benefits, they also introduce cybersecurity risks. Edge computing mitigates these risks by keeping sensitive data localized. By processing and analyzing data at the edge, the amount of data needing to travel across a potentially vulnerable network is reduced, thus minimizing the exposure to cyber threats. This layered security approach provides a more robust defense against potential attacks.

Enabling Advanced Analytics and AI at the Edge

Edge computing enables the deployment of sophisticated analytics and artificial intelligence algorithms directly within the factory. This allows for faster insights and more immediate actions based on the analyzed data. AI-powered systems can be used for anomaly detection, quality control, and process optimization, leading to significant improvements in efficiency and product quality. The on-site processing also reduces the reliance on cloud resources for complex computations, further accelerating the decision-making process.

Scalability and Future-Proofing Smart Factories

The modular nature of edge computing allows for easy scalability as factory needs evolve. As production expands or new technologies are integrated, the edge computing infrastructure can be easily adapted to meet the growing demands. This adaptability is crucial for future-proofing smart factories and ensuring their continued competitiveness in a rapidly changing technological landscape. It allows for a smooth and efficient transition to even more advanced technologies in the future.

Challenges and Considerations

While edge computing presents numerous advantages, some challenges need to be considered. Managing and maintaining a distributed edge computing infrastructure can be complex, requiring specialized skills and expertise. Ensuring data consistency and security across multiple edge nodes also demands careful planning and implementation. Addressing these challenges requires a strategic approach and investment in the right technologies and personnel. Please click here to learn about edge computing for smart factories.

Smart Factories AI’s Revolution in Manufacturing

The Dawn of Intelligent Automation

The manufacturing landscape is undergoing a seismic shift, driven by the integration of artificial intelligence (AI) into factories. This isn’t just about automating individual tasks; it’s about creating truly smart factories, where AI orchestrates and optimizes the entire production process, from design to delivery. This intelligent automation is leading to unprecedented levels of efficiency, flexibility, and quality, reshaping the future of manufacturing.

Predictive Maintenance: Preventing Downtime Before it Happens

One of the most impactful applications of AI in smart factories is predictive maintenance. By analyzing data from various sensors embedded in machinery, AI algorithms can predict potential equipment failures before they occur. This allows for proactive maintenance, minimizing downtime, reducing repair costs, and ultimately improving overall productivity. Instead of relying on scheduled maintenance, manufacturers can address issues only when necessary, optimizing resource allocation and maximizing uptime.

Quality Control: Ensuring Perfection Through AI-Powered Inspection

Maintaining consistent product quality is crucial in today’s competitive market. AI-powered vision systems are revolutionizing quality control by automating the inspection process with incredible accuracy. These systems can identify even the slightest defects that might be missed by human inspectors, leading to higher quality products and reduced waste. This real-time feedback loop allows for immediate adjustments to the production process, preventing further defects and ensuring consistent quality.

Optimizing Supply Chains: From Raw Materials to Finished Goods

Smart factories leverage AI to optimize the entire supply chain, from sourcing raw materials to delivering finished goods. AI algorithms can analyze vast amounts of data, including market trends, supplier performance, and transportation logistics, to predict demand, optimize inventory levels, and streamline the entire supply chain process. This leads to reduced lead times, improved inventory management, and lower costs.

Enhanced Production Planning and Scheduling: Maximizing Efficiency

AI is also transforming production planning and scheduling. By analyzing real-time data on machine availability, material inventory, and order demands, AI algorithms can create optimal production schedules that minimize lead times, maximize resource utilization, and improve overall factory efficiency. This dynamic scheduling capability allows manufacturers to adapt quickly to changing market demands and unforeseen events, ensuring that production remains efficient and responsive.

Robotics and Collaborative Robots (Cobots): Human-Machine Collaboration

The integration of robotics and collaborative robots (cobots) is another key element of smart factories. While traditional industrial robots perform repetitive tasks in isolation, cobots work alongside human workers, enhancing their capabilities and improving safety. AI empowers these robots with advanced capabilities like object recognition, path planning, and human-robot interaction, allowing for flexible and collaborative automation.

Data Analytics and Decision Making: The Power of Insights

The heart of a smart factory is its ability to collect, analyze, and interpret vast amounts of data. AI-powered analytics tools can uncover valuable insights that can inform strategic decisions, improve processes, and drive continuous improvement. This data-driven approach allows manufacturers to identify bottlenecks, optimize resource allocation, and make informed decisions based on real-time information, leading to a more efficient and profitable operation.

The Human Element in the Age of AI

While AI is transforming manufacturing, the human element remains crucial. The focus isn’t on replacing human workers but on augmenting their capabilities. Smart factory technologies empower workers with intelligent tools, enabling them to focus on higher-level tasks such as problem-solving, innovation, and managing complex systems. Reskilling and upskilling initiatives are essential to ensure that the workforce can adapt and thrive in this evolving environment.

The Future of Smart Factories: A Vision of Continuous Improvement

The journey towards truly smart factories is ongoing, with ongoing technological advancements pushing the boundaries of what’s possible. As AI continues to evolve, we can expect even more sophisticated applications in manufacturing, leading to greater efficiency, flexibility, sustainability, and competitiveness. The future of manufacturing is intelligent, adaptive, and human-centered. Read also about AI-enabled smart factories.

Smart Factories The Future of Manufacturing

What is a Smart Factory?

Imagine a manufacturing facility where machines talk to each other, predict their own maintenance needs, and adapt to changing demands in real-time. That’s the essence of a smart factory. It leverages cutting-edge technologies like the Internet of Things (IoT), artificial intelligence (AI), machine learning (ML), big data analytics, and cloud computing to optimize every aspect of the manufacturing process, from design and production to delivery and beyond. These interconnected systems create a flexible, responsive, and highly efficient production environment.

Key Technologies Powering Smart Factories

The transformation to a smart factory isn’t possible without several key technological pillars. IoT devices embedded in machinery and throughout the production line collect vast amounts of data on performance, efficiency, and potential issues. AI and ML algorithms then analyze this data to identify patterns, predict failures, and optimize production parameters. Cloud computing provides the necessary infrastructure to store and process this massive dataset, allowing for real-time analysis and decision-making. Robotics and automation play a crucial role in executing tasks with precision and speed, further enhancing efficiency. Finally, advanced cybersecurity measures are essential to protect the sensitive data and connected systems within the smart factory.

Enhanced Efficiency and Productivity

One of the most significant benefits of smart factories is the dramatic increase in efficiency and productivity. By automating repetitive tasks and optimizing resource allocation, manufacturers can reduce waste, minimize downtime, and accelerate production cycles. Real-time data analysis allows for immediate identification and resolution of bottlenecks, preventing costly delays. Predictive maintenance, based on AI analysis of machine data, helps prevent unexpected breakdowns, ensuring continuous operation and maximizing uptime. The overall result is a significant boost in output and a reduction in production costs.

Improved Product Quality and Consistency

Smart factories are not just about speed and efficiency; they also play a vital role in improving product quality and consistency. By monitoring every stage of the manufacturing process with precision, these factories can identify and correct deviations from the desired specifications in real-time. This ensures that every product meets the highest quality standards, minimizing defects and improving customer satisfaction. Moreover, the data collected throughout the process provides valuable feedback for continuous improvement, enabling manufacturers to refine their processes and produce even higher-quality products over time.

Greater Flexibility and Adaptability

In today’s dynamic market, the ability to adapt quickly to changing demands is paramount. Smart factories excel in this area, thanks to their flexible and adaptable nature. They can easily adjust production schedules and reconfigure their operations to meet fluctuating customer orders or respond to unforeseen circumstances. This agility allows manufacturers to remain competitive in a rapidly evolving market, ensuring they can quickly adapt to new trends and customer preferences. This enhanced flexibility also enables manufacturers to quickly introduce new products or adapt existing ones to meet evolving needs.

Enhanced Supply Chain Management

Smart factories extend their benefits beyond the factory floor. They facilitate enhanced supply chain management by providing real-time visibility into the entire supply chain. Through data integration and sophisticated analytics, manufacturers gain insights into inventory levels, supplier performance, and potential disruptions. This allows them to optimize logistics, reduce lead times, and ensure a smoother, more efficient supply chain. Predictive analytics can help anticipate potential supply chain issues, allowing manufacturers to proactively mitigate risks and prevent disruptions.

Challenges in Implementing Smart Factories

While the potential benefits of smart factories are immense, the transition to a smart factory isn’t without challenges. The initial investment in new technologies and infrastructure can be substantial. Integrating various systems and ensuring seamless data flow can be complex and require significant expertise. Furthermore, cybersecurity risks need to be carefully considered and addressed to protect sensitive data and prevent disruptions. Finally, the workforce requires training and upskilling to effectively manage and utilize the new technologies.

The Future of Manufacturing: A Collaborative Ecosystem

The future of manufacturing is not just about individual smart factories; it’s about the creation of a collaborative ecosystem. Smart factories will increasingly interact with each other, sharing data and insights to optimize entire supply chains. This collaborative approach will lead to further efficiency gains, enhanced innovation, and a more resilient and sustainable manufacturing sector. The journey towards a fully realized smart factory ecosystem will be evolutionary, but the potential rewards are substantial, promising a future of more efficient, responsive, and sustainable manufacturing. Click here to learn about smart factories in Industry 4.0.