The Dawn of Intelligent Automation

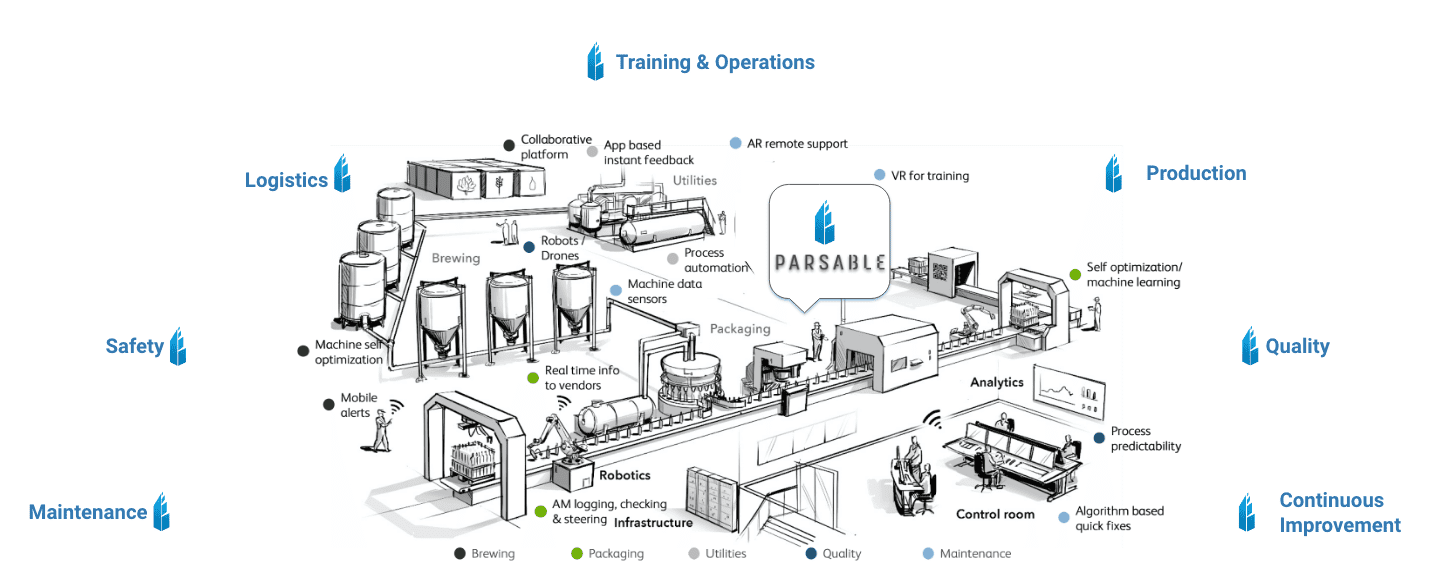

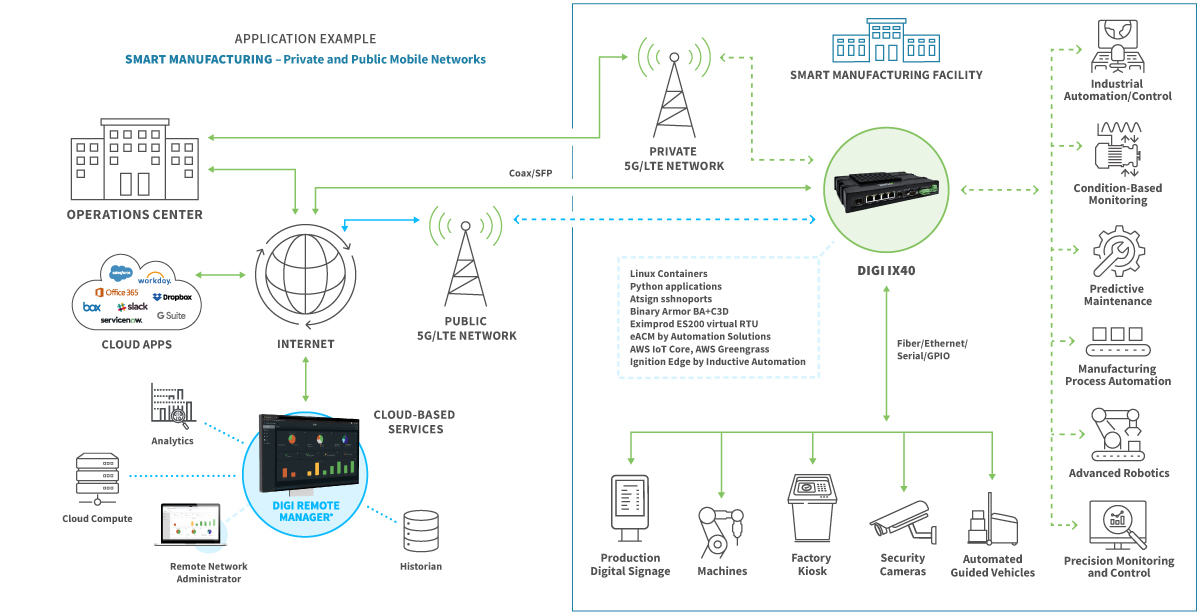

The manufacturing landscape is undergoing a seismic shift, driven by the integration of artificial intelligence (AI) into factories. This isn’t just about automating individual tasks; it’s about creating truly smart factories, where AI orchestrates and optimizes the entire production process, from design to delivery. This intelligent automation is leading to unprecedented levels of efficiency, flexibility, and quality, reshaping the future of manufacturing.

Predictive Maintenance: Preventing Downtime Before it Happens

One of the most impactful applications of AI in smart factories is predictive maintenance. By analyzing data from various sensors embedded in machinery, AI algorithms can predict potential equipment failures before they occur. This allows for proactive maintenance, minimizing downtime, reducing repair costs, and ultimately improving overall productivity. Instead of relying on scheduled maintenance, manufacturers can address issues only when necessary, optimizing resource allocation and maximizing uptime.

Quality Control: Ensuring Perfection Through AI-Powered Inspection

Maintaining consistent product quality is crucial in today’s competitive market. AI-powered vision systems are revolutionizing quality control by automating the inspection process with incredible accuracy. These systems can identify even the slightest defects that might be missed by human inspectors, leading to higher quality products and reduced waste. This real-time feedback loop allows for immediate adjustments to the production process, preventing further defects and ensuring consistent quality.

Optimizing Supply Chains: From Raw Materials to Finished Goods

Smart factories leverage AI to optimize the entire supply chain, from sourcing raw materials to delivering finished goods. AI algorithms can analyze vast amounts of data, including market trends, supplier performance, and transportation logistics, to predict demand, optimize inventory levels, and streamline the entire supply chain process. This leads to reduced lead times, improved inventory management, and lower costs.

Enhanced Production Planning and Scheduling: Maximizing Efficiency

AI is also transforming production planning and scheduling. By analyzing real-time data on machine availability, material inventory, and order demands, AI algorithms can create optimal production schedules that minimize lead times, maximize resource utilization, and improve overall factory efficiency. This dynamic scheduling capability allows manufacturers to adapt quickly to changing market demands and unforeseen events, ensuring that production remains efficient and responsive.

Robotics and Collaborative Robots (Cobots): Human-Machine Collaboration

The integration of robotics and collaborative robots (cobots) is another key element of smart factories. While traditional industrial robots perform repetitive tasks in isolation, cobots work alongside human workers, enhancing their capabilities and improving safety. AI empowers these robots with advanced capabilities like object recognition, path planning, and human-robot interaction, allowing for flexible and collaborative automation.

Data Analytics and Decision Making: The Power of Insights

The heart of a smart factory is its ability to collect, analyze, and interpret vast amounts of data. AI-powered analytics tools can uncover valuable insights that can inform strategic decisions, improve processes, and drive continuous improvement. This data-driven approach allows manufacturers to identify bottlenecks, optimize resource allocation, and make informed decisions based on real-time information, leading to a more efficient and profitable operation.

The Human Element in the Age of AI

While AI is transforming manufacturing, the human element remains crucial. The focus isn’t on replacing human workers but on augmenting their capabilities. Smart factory technologies empower workers with intelligent tools, enabling them to focus on higher-level tasks such as problem-solving, innovation, and managing complex systems. Reskilling and upskilling initiatives are essential to ensure that the workforce can adapt and thrive in this evolving environment.

The Future of Smart Factories: A Vision of Continuous Improvement

The journey towards truly smart factories is ongoing, with ongoing technological advancements pushing the boundaries of what’s possible. As AI continues to evolve, we can expect even more sophisticated applications in manufacturing, leading to greater efficiency, flexibility, sustainability, and competitiveness. The future of manufacturing is intelligent, adaptive, and human-centered. Read also about AI-enabled smart factories.