Enhanced Collaboration and Design

The metaverse offers a transformative shift in how manufacturing teams collaborate. Imagine engineers from different continents, wearing VR headsets, working together on a 3D model of a new engine. They can manipulate the design in real-time, discuss changes instantly, and visually inspect every detail, all without ever leaving their desks. This drastically reduces design cycles, improves communication, and fosters a more intuitive and collaborative design process. No more endless email chains or confusing 2D blueprints; the metaverse provides a shared, immersive workspace for seamless collaboration.

Digital Twins for Predictive Maintenance

One of the most exciting applications of the metaverse in manufacturing is the creation and implementation of digital twins. A digital twin is a virtual replica of a physical asset, such as a machine or an entire factory floor. By using sensor data and AI, these digital twins can simulate real-world conditions and predict potential issues before they occur. This allows for proactive maintenance, reducing downtime, extending the lifespan of equipment, and significantly improving operational efficiency. Instead of reacting to failures, manufacturers can anticipate and prevent them, leading to significant cost savings and increased productivity.

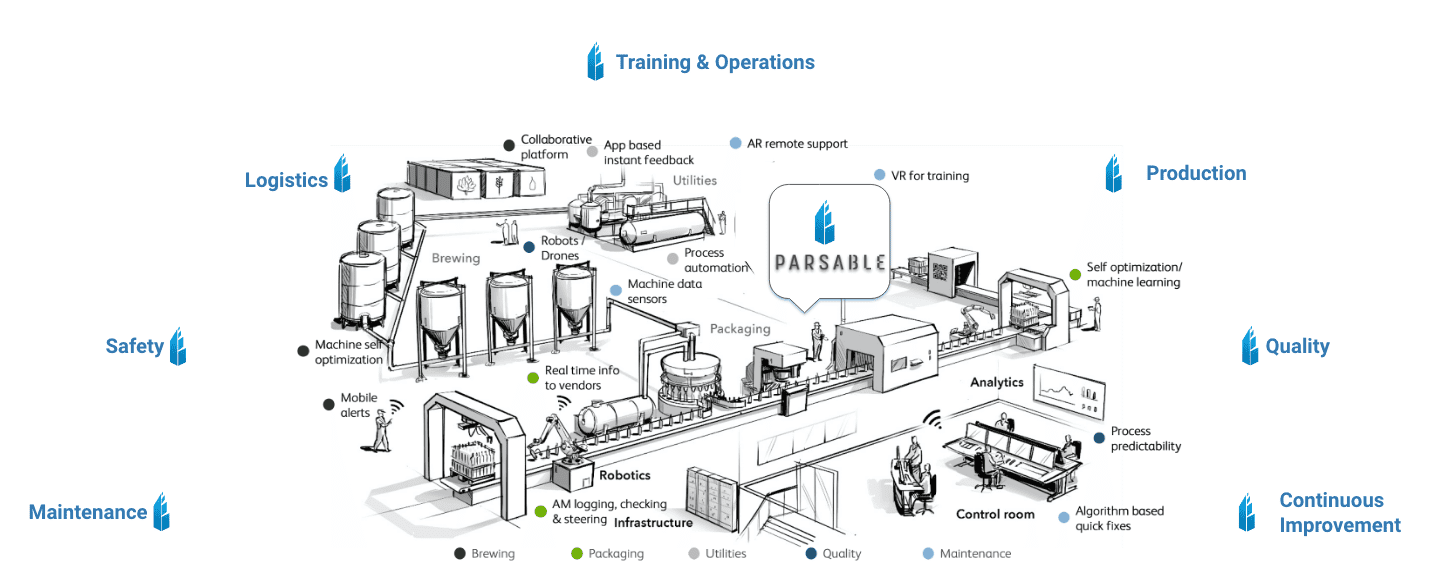

Streamlined Training and Onboarding

Training new employees in a manufacturing environment can be complex, costly, and potentially dangerous. The metaverse provides a safe and effective alternative. New hires can undergo virtual training simulations, learning to operate machinery, understand safety protocols, and troubleshoot problems in a risk-free environment. This immersive learning experience is more engaging and effective than traditional methods, leading to faster onboarding and a more skilled workforce. Companies can even simulate complex scenarios, like equipment malfunctions or emergency situations, allowing trainees to develop crucial problem-solving skills in a controlled setting.

Improved Supply Chain Management

Supply chain disruptions have become a major challenge for manufacturers. The metaverse offers tools to improve visibility and efficiency throughout the supply chain. By creating a digital representation of the entire supply chain, manufacturers can track the movement of goods in real-time, anticipate potential delays, and optimize logistics. This improved transparency allows for quicker responses to disruptions, better inventory management, and reduced lead times, ultimately leading to more resilient and responsive supply chains. The virtual environment provides a platform for better communication and coordination among all stakeholders, from suppliers to distributors.

Remote Operations and Monitoring

In industries with remote or hazardous work environments, the metaverse offers a revolutionary approach to operations and monitoring. Workers can remotely control and monitor machinery and processes through VR interfaces, reducing the need for on-site personnel in dangerous situations. This not only improves safety but also allows for more efficient and precise control of operations. Imagine technicians remotely guiding complex repairs using augmented reality overlays, providing real-time instructions to on-site personnel, or monitoring the performance of equipment from a central control room, all through a metaverse platform.

Enhanced Customer Experience

The metaverse isn’t just limited to internal operations; it can also revolutionize the customer experience. Manufacturers can create virtual showrooms where customers can explore and interact with products in a realistic and immersive environment. This provides a more engaging and informative pre-purchase experience, allowing customers to better understand the product’s features and benefits before making a purchase. Companies can even offer virtual consultations and personalized product demonstrations, leading to increased customer satisfaction and brand loyalty. This immersive approach builds a stronger connection between the manufacturer and the customer.

Addressing the Challenges of Metaverse Adoption

While the potential benefits are significant, the adoption of metaverse technologies in manufacturing also faces challenges. The high initial investment in hardware and software, the need for skilled personnel to develop and implement metaverse applications, and the integration with existing systems are all considerable hurdles. Furthermore, ensuring data security and privacy in a shared virtual environment is crucial for successful implementation. Overcoming these challenges requires collaboration between manufacturers, technology providers, and regulatory bodies to establish standards and best practices for metaverse adoption in the manufacturing sector. This collaborative effort will drive the wider acceptance and integration of this revolutionary technology. Read also about the metaverse for smart factories.