Inventory Optimization Global Market Growth Insights

The global landscape of supply chain management is undergoing a significant shift, driven by increasing complexity, evolving customer demands, and the ever-present pressure to reduce costs. At the heart of this evolution lies Inventory Optimization, a critical process that enables businesses to efficiently manage their stock levels, minimize waste, and maximize profitability. The global market for Inventory Optimization solutions is experiencing substantial growth, fueled by the increasing recognition of its benefits across various industries.

Key Takeaways:

- The global Inventory Optimization market is expanding rapidly due to the need for improved efficiency and reduced costs in supply chains.

- Demand forecasting and advanced analytics are key components of effective Inventory Optimization strategies.

- Cloud-based solutions and the integration of AI and machine learning are driving innovation in the Inventory Optimization market.

- Businesses that embrace Inventory Optimization can gain a competitive advantage by improving service levels, reducing inventory holding costs, and minimizing stockouts.

Understanding the Growth Drivers of Inventory Optimization

The growth of the Inventory Optimization market is propelled by several factors. First, the increasing complexity of global supply chains necessitates more sophisticated tools for managing inventory across multiple locations and channels. Companies are seeking solutions that can provide real-time visibility into their inventory positions and enable them to make data-driven decisions about replenishment and allocation.

Second, the rise of e-commerce and omnichannel retail has placed greater demands on inventory management. Customers expect fast delivery times and a wide selection of products, which requires retailers to hold more inventory in strategic locations. Inventory Optimization helps businesses balance the need for high service levels with the goal of minimizing inventory holding costs.

Third, advancements in technology, such as cloud computing, big data analytics, and machine learning, are making Inventory Optimization solutions more accessible and effective. These technologies enable businesses to process large volumes of data, identify patterns, and make accurate forecasts about future demand. As a result, companies can optimize their inventory levels and reduce the risk of stockouts or overstocks.

We are seeing a major shift toward solutions that integrate seamlessly with existing enterprise resource planning (ERP) and supply chain management (SCM) systems, providing a unified view of inventory across the entire organization.

Leveraging Demand Forecasting for Inventory Optimization

Accurate demand forecasting is essential for effective Inventory Optimization. By predicting future demand, businesses can proactively adjust their inventory levels to meet customer needs without holding excessive stock. Demand forecasting involves analyzing historical sales data, market trends, and other relevant factors to estimate future demand for specific products.

Advanced forecasting techniques, such as machine learning algorithms, can improve the accuracy of demand forecasts by identifying complex patterns and relationships in the data. These algorithms can also account for external factors, such as seasonality, promotions, and economic conditions, which can impact demand. Businesses are turning to sophisticated software solutions that offer statistical forecasting, collaborative planning, and demand sensing capabilities to achieve better forecasting accuracy.

By leveraging demand forecasting, companies can optimize their inventory levels, reduce the risk of stockouts, and improve customer service levels. This proactive approach allows them to respond quickly to changes in demand and minimize the impact of unexpected events, such as supply chain disruptions. It allows us to react with speed and agility.

The Impact of Cloud and AI on Inventory Optimization

Cloud-based Inventory Optimization solutions are gaining popularity due to their scalability, flexibility, and affordability. Cloud solutions enable businesses to access advanced analytics and optimization tools without the need for significant upfront investment in hardware and software. They also facilitate collaboration among different departments and stakeholders, improving decision-making and coordination.

Artificial intelligence (AI) and machine learning (ML) are playing an increasingly important role in Inventory Optimization. AI-powered solutions can automate many of the manual tasks involved in inventory management, such as demand forecasting, replenishment planning, and inventory allocation. ML algorithms can also identify patterns and anomalies in the data that humans may miss, providing valuable insights for improving inventory performance.

For example, AI can be used to optimize safety stock levels by analyzing historical demand variability and lead times. It can also be used to identify slow-moving or obsolete inventory, allowing businesses to take proactive measures to reduce waste and improve inventory turnover. The integration of AI and ML is transforming Inventory Optimization from a reactive process to a proactive and predictive one.

Strategies for Successful Inventory Optimization Implementation

Implementing Inventory Optimization successfully requires a well-defined strategy and a commitment to continuous improvement. Businesses should start by assessing their current inventory management processes and identifying areas for improvement. This involves analyzing historical data, conducting interviews with stakeholders, and benchmarking against industry best practices.

Next, businesses should select an Inventory Optimization solution that meets their specific needs and requirements. This involves evaluating different vendors, comparing features and capabilities, and conducting pilot projects to test the solution in a real-world

Smart Inventory The Future of Stock Management

The Rise of Smart Inventory: A Paradigm Shift in Stock Management

For decades, inventory management has relied on manual processes, spreadsheets, and guesswork. This often resulted in overstocking, stockouts, and significant financial losses. However, the emergence of smart inventory systems is revolutionizing the way businesses manage their stock, offering a level of precision and efficiency previously unimaginable. Smart inventory leverages technology, data analysis, and automation to streamline every aspect of the supply chain, from forecasting demand to optimizing warehouse operations.

Real-time Visibility and Data-Driven Decisions

One of the key benefits of smart inventory is the ability to gain real-time visibility into stock levels. Automated systems constantly track inventory movements, providing up-to-the-minute data on what’s in stock, where it is, and when it’s expected to arrive. This eliminates the reliance on outdated spreadsheets and manual counts, providing a much clearer picture of the current inventory status. This real-time data forms the basis for data-driven decisions, allowing businesses to make informed choices about ordering, pricing, and resource allocation, ultimately minimizing waste and maximizing profitability.

Predictive Analytics: Forecasting Future Demand

Smart inventory systems go beyond simply tracking current inventory; they leverage predictive analytics to forecast future demand. By analyzing historical sales data, market trends, seasonality, and even external factors like weather patterns, these systems can anticipate future needs with remarkable accuracy. This allows businesses to proactively adjust their ordering schedules, preventing stockouts and minimizing the risk of holding excess inventory. This predictive capability is particularly valuable in industries with fluctuating demand or seasonal peaks.

Automation and Efficiency: Streamlining Warehouse Operations

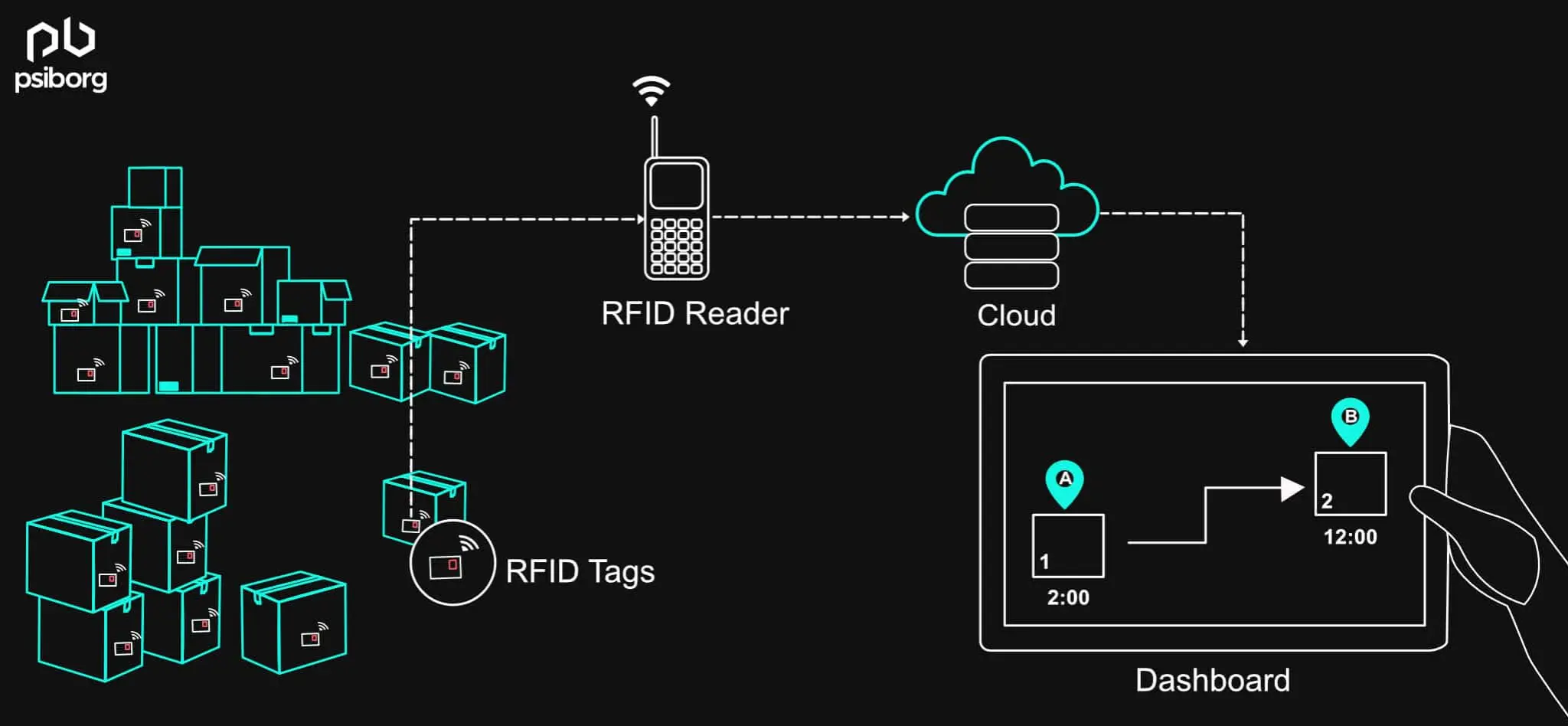

Smart inventory systems are not just about data; they also automate many of the time-consuming tasks associated with inventory management. Automated stock replenishment systems automatically trigger orders when stock levels fall below predetermined thresholds. Warehouse management systems (WMS) optimize storage locations, track item movements, and guide workers through picking and packing processes, improving efficiency and reducing errors. Radio-frequency identification (RFID) technology allows for seamless tracking of individual items, providing granular visibility and further enhancing accuracy.

Improved Accuracy and Reduced Costs: The Financial Benefits

The improved accuracy provided by smart inventory translates directly into significant cost savings. Reduced stockouts mean fewer lost sales and happier customers. Minimizing overstocking frees up capital that can be invested elsewhere in the business. Automation streamlines operations, reducing labor costs and increasing productivity. The overall effect is a more efficient and profitable operation, with less waste and greater control over inventory levels. The return on investment (ROI) for implementing a smart inventory system is often substantial.

Enhanced Customer Satisfaction: Meeting Demand Consistently

Smart inventory systems ultimately contribute to enhanced customer satisfaction. By accurately forecasting demand and ensuring that goods are available when and where they are needed, businesses can meet customer expectations consistently. Reduced stockouts mean fewer disappointed customers, leading to increased customer loyalty and repeat business. This positive impact on customer experience is a significant intangible benefit of implementing a smart inventory system.

Integration with Other Systems: A Holistic Approach

Modern smart inventory systems are designed to integrate seamlessly with other business systems, such as enterprise resource planning (ERP) software, point-of-sale (POS) systems, and customer relationship management (CRM) systems. This integration provides a holistic view of the business, allowing for better coordination and decision-making across different departments. Data flows seamlessly between systems, providing a single source of truth for inventory information and improving overall business efficiency.

The Future of Smart Inventory: Continued Innovation

The field of smart inventory is constantly evolving, with ongoing innovation driving further improvements in accuracy, efficiency, and cost savings. Emerging technologies such as artificial intelligence (AI) and machine learning (ML) are being incorporated into inventory management systems, allowing for even more sophisticated forecasting and optimization. The future of inventory management will undoubtedly be driven by smart technologies, paving the way for greater agility, responsiveness, and profitability for businesses of all sizes. Please click here to learn more about smart inventory management.