The remanufacturing sector is experiencing a significant surge in global demand. This growth is fueled by a confluence of factors, including increased environmental awareness, stricter regulations, and the compelling economic advantages remanufacturing processes offer. Businesses and consumers alike are increasingly recognizing the value in extending the lifespan of products, reducing waste, and conserving resources. The shift towards a more circular economy model is propelling remanufacturing into the mainstream.

Key Takeaways:

- The global remanufacturing market is experiencing rapid growth due to environmental and economic pressures.

- Remanufacturing processes offer a sustainable alternative to traditional manufacturing, reducing waste and conserving resources.

- The automotive and industrial sectors are leading the way in adopting remanufacturing practices.

- Government incentives and consumer awareness are further driving the adoption of remanufacturing worldwide.

Understanding the Growth of Remanufacturing Processes

The growth of remanufacturing processes is not just a trend; it’s a fundamental shift in how we approach production and consumption. Traditional “take-make-dispose” models are increasingly unsustainable in a world facing resource scarcity and environmental challenges. Remanufacturing provides a viable and profitable alternative. It involves restoring used products to like-new condition through a rigorous process of disassembly, cleaning, inspection, repair, and replacement of worn or obsolete parts. This process allows us to reuse existing materials, significantly reducing the demand for new raw materials and the energy required to extract and process them.

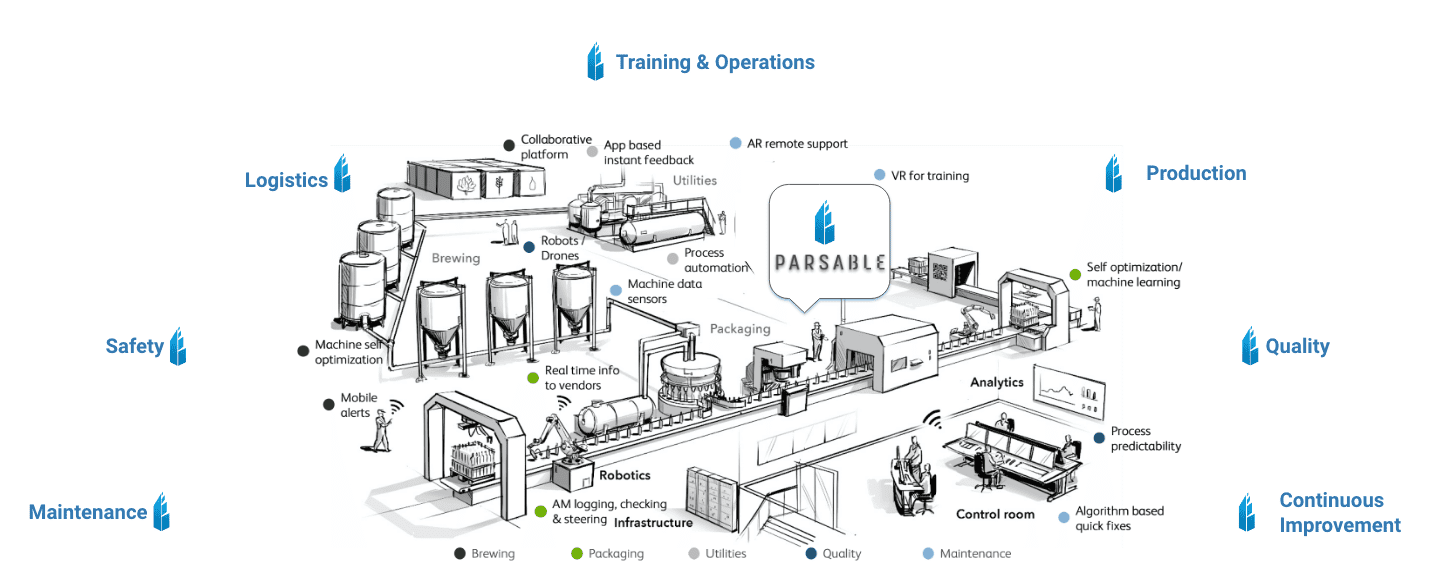

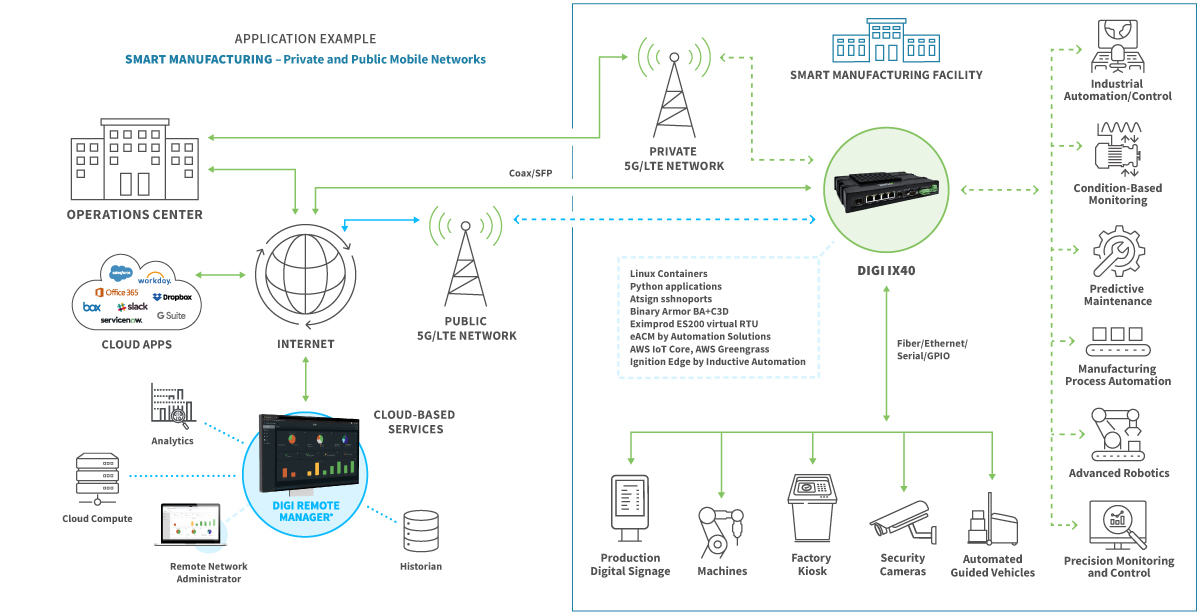

Furthermore, technological advancements are making remanufacturing processes more efficient and cost-effective. Automated systems, advanced diagnostic tools, and improved materials are contributing to higher quality remanufactured products that can compete with new products in terms of performance and reliability. This technological progress is empowering businesses to scale up their remanufacturing operations and reach a wider customer base.

Economic Advantages of Remanufacturing Processes

Beyond its environmental benefits, remanufacturing processes offer significant economic advantages for both businesses and consumers. For manufacturers, remanufacturing can create new revenue streams by extending the life cycle of their products and capturing value from returned or used items. It also allows them to reduce their dependence on volatile raw material prices and mitigate supply chain disruptions. This can lead to greater profitability and resilience in the face of economic uncertainty.

For consumers, remanufactured products often come with a lower price tag than new products, making them an attractive option for those seeking value for money. This affordability, combined with the assurance of quality and performance, is driving increased consumer demand for remanufactured goods. Additionally, the growth of the remanufacturing sector is creating new jobs and opportunities in local economies, further contributing to its economic appeal. The rise of online marketplaces and e-commerce platforms has also made it easier for consumers to access and purchase remanufactured products. This increased accessibility is playing a crucial role in driving market growth and expanding the reach of the remanufacturing industry.

The Role of Automotive and Industrial Remanufacturing Processes

The automotive and industrial sectors are at the forefront of the remanufacturing movement. In the automotive industry, remanufactured parts such as engines, transmissions, and alternators are widely used in vehicle repairs and maintenance. These parts offer a cost-effective and environmentally friendly alternative to new parts, helping to reduce waste and conserve resources. The automotive industry’s established infrastructure for core collection and distribution has played a significant role in the success of automotive remanufacturing.

Similarly, in the industrial sector, remanufacturing processes are used to restore and upgrade heavy machinery, equipment, and components. This is particularly important in industries such as manufacturing, mining, and construction, where equipment is often subject to harsh operating conditions and high levels of wear and tear. Remanufacturing allows companies to extend the lifespan of their assets, reduce downtime, and lower maintenance costs. As industries face increasing pressure to reduce their environmental footprint and improve resource efficiency, remanufacturing is becoming an increasingly attractive and necessary solution. The focus on predictive maintenance and data analytics is further optimizing remanufacturing processes in these sectors. These technologies allow us to better anticipate component failures and schedule remanufacturing activities proactively, minimizing disruptions and maximizing efficiency.

Government Support and Consumer Awareness for Remanufacturing Processes

Government policies and consumer awareness are playing a crucial role in accelerating the adoption of remanufacturing processes worldwide. Governments are increasingly recognizing the environmental and economic benefits of remanufacturing and are implementing policies to support its growth. These policies may include tax incentives, subsidies, and regulations that promote the use of remanufactured products and encourage businesses to adopt remanufacturing practices. By creating a favorable regulatory environment, governments can help to level the playing field and encourage greater investment in the remanufacturing sector.

Consumer awareness is also a key driver of market growth. As more consumers become aware of the environmental and economic benefits of remanufactured products, they are increasingly choosing these products over new alternatives. This increased demand is creating a virtuous cycle, encouraging more businesses to offer remanufactured products and driving further innovation in remanufacturing processes. Educational campaigns, labeling initiatives, and certifications are all helping to increase consumer trust and confidence in remanufactured products. We need to continue to educate consumers about the value and quality of remanufactured goods to further drive market growth and promote a more sustainable consumption model.