Smart Factory Software The Future of Manufacturing

The Rise of the Smart Factory

The manufacturing landscape is undergoing a dramatic transformation, driven by the convergence of advanced technologies like artificial intelligence (AI), the Internet of Things (IoT), big data analytics, and cloud computing. This convergence is fueling the rise of the smart factory, a highly automated and interconnected facility where data-driven insights optimize every aspect of production, from design and planning to manufacturing and delivery. No longer are factories simply places where goods are made; they’re becoming sophisticated, responsive ecosystems capable of adapting to changing market demands with unprecedented agility.

Smart Factory Software: The Brains of the Operation

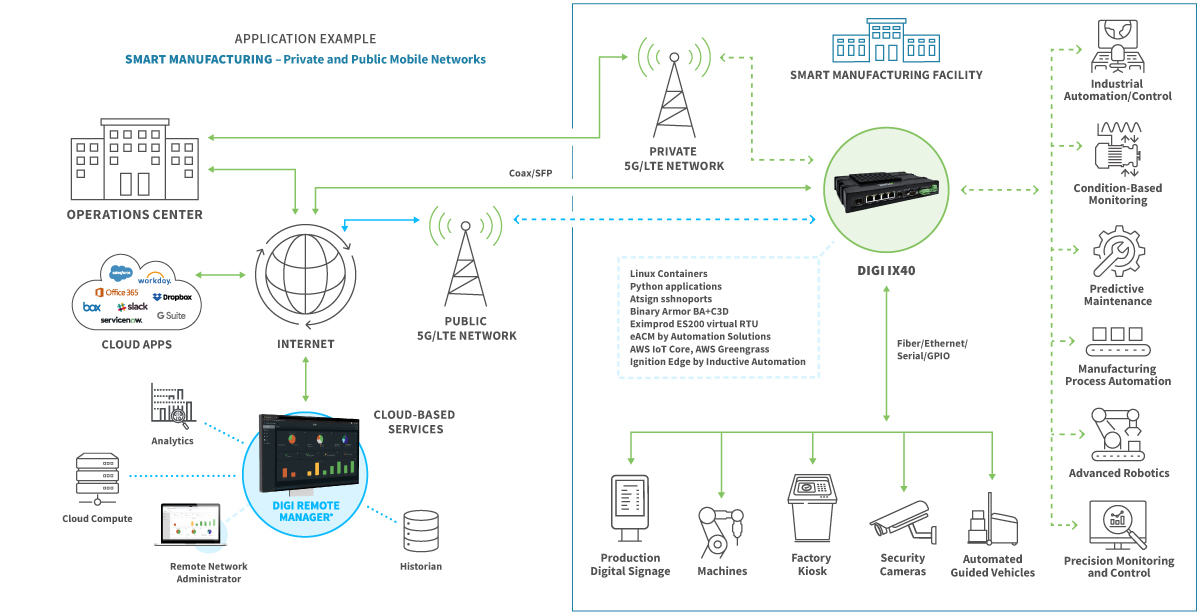

At the heart of the smart factory lies sophisticated software. This isn’t just the traditional manufacturing execution system (MES) software; it’s a much more comprehensive and integrated platform that orchestrates the entire factory ecosystem. This software integrates data from various sources – machines, sensors, ERP systems, supply chain management systems – providing a single source of truth for all factory operations. This unified view enables real-time monitoring, predictive maintenance, and proactive adjustments to optimize efficiency and minimize downtime.

Predictive Maintenance: Preventing Problems Before They Happen

One of the most significant benefits of smart factory software is its ability to predict and prevent equipment failures. By analyzing data from sensors embedded in machinery, the software can identify patterns that indicate potential problems before they escalate into costly breakdowns. This predictive maintenance capability significantly reduces downtime, improves production efficiency, and extends the lifespan of equipment. Rather than relying on scheduled maintenance, factories can now perform maintenance only when and where it’s actually needed, maximizing uptime and minimizing waste.

Real-time Monitoring and Control: Staying Ahead of the Curve

Smart factory software provides real-time visibility into every aspect of the manufacturing process. Operators can monitor production in real time, identify bottlenecks, and make adjustments on the fly to keep production flowing smoothly. This real-time monitoring capability allows for immediate responses to unexpected events, minimizing disruptions and maximizing efficiency. The ability to react quickly to changing conditions is crucial in today’s dynamic market, where responsiveness is key to competitiveness.

Data Analytics: Unlocking Hidden Insights

The vast amounts of data generated by a smart factory can be overwhelming without the right tools to analyze it. Smart factory software incorporates advanced data analytics capabilities that can sift through this data, identify trends, and extract valuable insights. This data can be used to improve production processes, optimize resource allocation, reduce waste, and improve product quality. By uncovering hidden patterns and correlations within the data, manufacturers can make more informed decisions and continuously improve their operations.

Enhanced Collaboration and Communication: Breaking Down Silos

Traditional manufacturing often suffers from information silos, where different departments operate in isolation. Smart factory software breaks down these silos by providing a central platform for collaboration and communication. All stakeholders – from engineers and operators to managers and suppliers – can access the same information in real time, fostering better communication and collaboration. This enhanced communication streamlines processes, reduces errors, and improves overall efficiency.

Supply Chain Optimization: From Raw Materials to Finished Goods

Smart factory software extends beyond the factory floor, encompassing the entire supply chain. By integrating data from suppliers, distributors, and logistics providers, the software enables real-time visibility into the entire supply chain. This visibility enables better inventory management, optimized logistics, and improved supply chain responsiveness. Manufacturers can proactively address potential disruptions and ensure a steady flow of materials and components, minimizing delays and ensuring timely delivery of finished goods.

The Future of Manufacturing: A Seamless and Agile Ecosystem

Smart factory software is not just a collection of individual technologies; it’s a transformative force reshaping the future of manufacturing. It’s creating a more agile, efficient, and responsive industry capable of adapting to the ever-changing demands of the global market. The factories of tomorrow will be seamlessly interconnected ecosystems, leveraging data-driven insights to optimize every aspect of production, delivering higher quality products at lower costs, and responding to market fluctuations with unprecedented speed and agility. Read also about iot software for smart factories.

Vertical SaaS Explained What It Means For You

Understanding Vertical SaaS

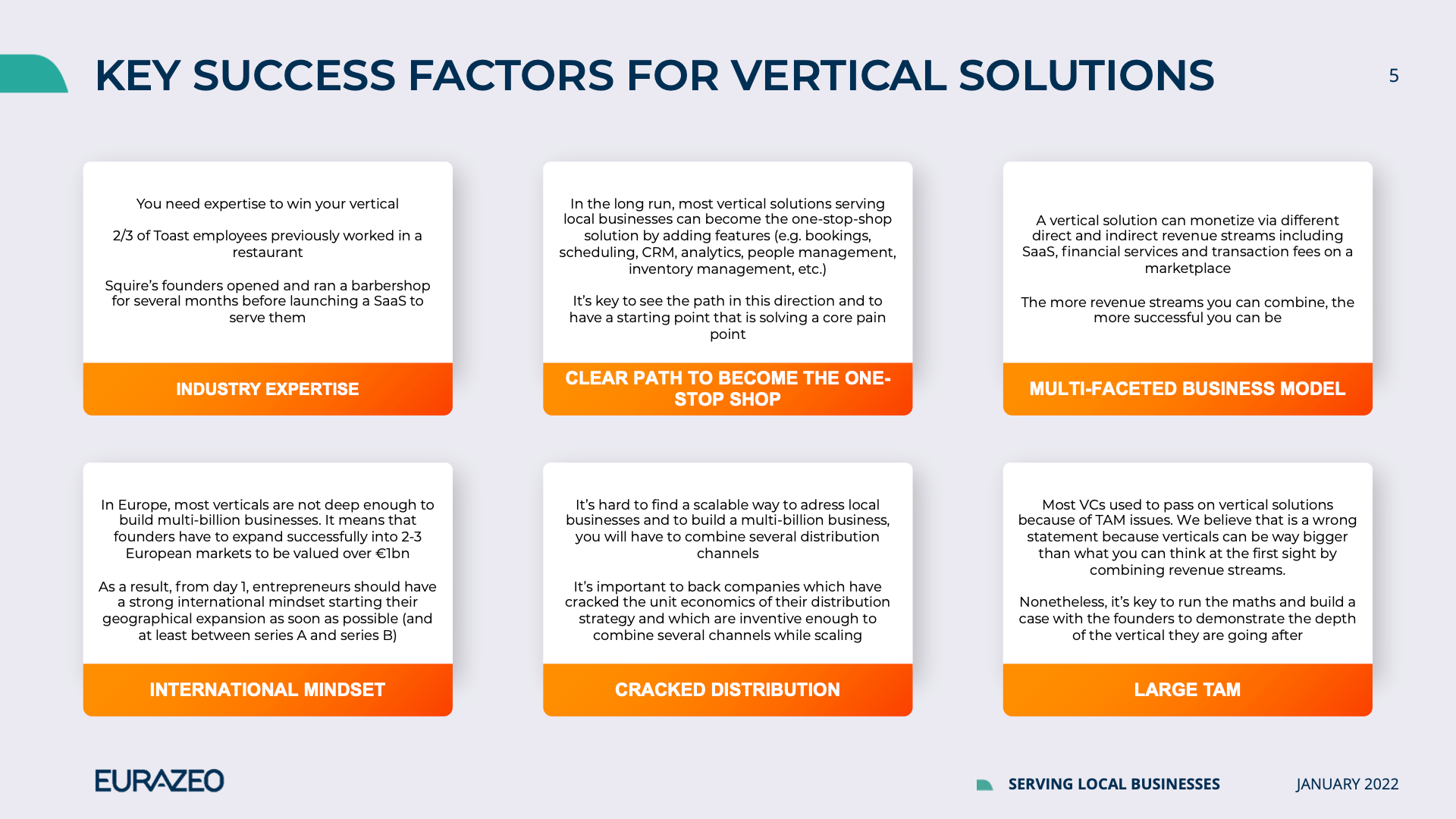

Vertical SaaS, or Software as a Service, is a specific type of software designed to cater to the unique needs of a particular industry or niche. Unlike horizontal SaaS, which aims to serve a broad range of businesses regardless of their sector (think CRM systems or project management tools), vertical SaaS solutions are deeply specialized. They’re built with the specific workflows, regulations, and pain points of a particular vertical in mind. Imagine accounting software tailored exclusively for dentists, or a customer relationship management (CRM) system specifically designed for breweries – that’s vertical SaaS in action.

The Benefits of Vertical SaaS for Businesses

For businesses operating within a specific vertical, the advantages of vertical SaaS are significant. These solutions often come pre-loaded with industry-specific features and functionalities that save time and money. No more struggling to adapt generic software to your unique needs; vertical SaaS is built to work seamlessly with your existing processes. This integration boosts efficiency, reduces the need for extensive customization, and simplifies training for employees. The deep understanding of industry regulations and best practices built into the software also minimizes compliance risks.

How Vertical SaaS Differs from Horizontal SaaS

The key difference lies in the scope and focus. Horizontal SaaS aims for broad applicability, offering generic features that can be adapted to different industries. This broad approach can lead to a lack of specific features relevant to your business, requiring workarounds and potentially costly customizations. Vertical SaaS, conversely, focuses on a specific industry. It delivers features tailored to the industry’s unique challenges and opportunities, resulting in a more streamlined and efficient solution that’s ready to use from the get-go. The level of customization required is significantly reduced, leading to faster implementation and lower costs.

Examples of Vertical SaaS in Action

Consider the healthcare industry. A horizontal CRM might track customer interactions, but a vertical SaaS solution for healthcare practices would integrate with electronic health records (EHRs), manage patient scheduling, and comply with HIPAA regulations – features crucial to the healthcare sector but irrelevant to, say, a retail business. Similarly, a construction management software would integrate with project blueprints, track material costs specifically relevant to the construction industry, and manage worker certifications, unlike a generic project management tool.

Choosing the Right Vertical SaaS Solution

Selecting the right vertical SaaS solution requires careful consideration. Begin by identifying your specific needs and challenges. Research different vendors offering solutions within your industry. Look for software with a strong track record, positive user reviews, and robust customer support. Consider scalability; choose a solution that can grow with your business. Don’t hesitate to request demos and trials to assess the software’s usability and functionality before committing to a long-term contract. A well-chosen vertical SaaS solution can be a game-changer for your business.

The Future of Vertical SaaS

The vertical SaaS market is expanding rapidly. As businesses increasingly recognize the benefits of specialized solutions, the demand for industry-specific software is only expected to grow. We’re likely to see further innovation in this space, with solutions becoming even more tailored and integrated with other technologies. Artificial intelligence and machine learning are poised to play a significant role, enhancing automation and providing deeper insights into business operations within specific verticals. This increased specialization will lead to greater efficiency and productivity for businesses across various industries.

Cost Considerations and ROI of Vertical SaaS

While the initial investment in vertical SaaS might seem higher compared to a generic horizontal solution, the long-term return on investment (ROI) is often significant. The increased efficiency, reduced customization costs, and minimized compliance risks can lead to substantial cost savings. Furthermore, the specialized features often translate to improved productivity and better decision-making, ultimately boosting profitability. Carefully evaluating the total cost of ownership (TCO), including implementation, training, and ongoing support, against the potential benefits is crucial for making an informed decision.

Security and Data Privacy in Vertical SaaS

Security and data privacy are paramount considerations when selecting any SaaS solution, particularly within regulated industries. Look for vendors who comply with relevant industry standards and regulations (like HIPAA in healthcare or GDPR in Europe). Ensure the vendor has robust security measures in place to protect your sensitive data. Transparency regarding data security practices is crucial. Don’t hesitate to ask detailed questions about the vendor’s security protocols and data encryption methods to ensure your business and customer data remains safe. Read also about what vertical SaaS means.